Specialty Machine Tools & Equipment

Fuji Manufacturing

Fuji Manufacturing provides state of the arc blasting systems customized for each user needs. We base ourselves on providing our clients with consultations with an emphasis on today's “technology”. We propose systems that will be an appropriate solution to specific business needs. Not only providing the highest -level technology in spraying , sorting and collecting abrasive, but also in stably activating the equipment and detecting errors, and inspecting and maintain processing specifications. Moreover, our manufacturing and inspection department that embody those proposal have the largest scale and most advanced environment in Tokyo.

-

Pneuma-Blaster

PNEUMA BLASTER deals with processing from general processing to Ultra precision processing (processing for workpiece from small sized workpiece (wafer) to large sized workpiece needs higher precision for short time). We have had many track records for manufacture and sell of automatic machine for their processing.

-

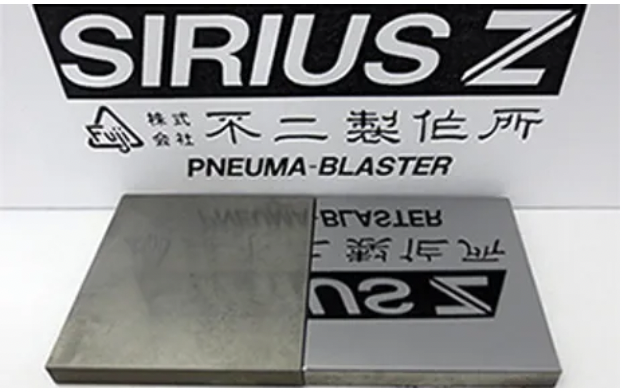

Sirius Processing

SIRIUS PROCESSING has ability to operate continuously by using our developed media without regeneration. Burrs while keeping sharpness for edge of workpiece. Generates highly functional surface with low damage. We have had many track records for manufacture and sell of automatic machine for Sirius processing.

-

WPC Treatment

WPC TREATMENT extends lifespan of metal parts, die assembly, blades, and tools. We have had many track records for manufacture and sell of automatic machine for WPC treatment.

Burr Removal for Fine Tips and Edges

Expansion of lifespan and prevention of initial chipping with removal of burrs after abrasion or mechanical processing of an end mill, drill, hob, gear, etc.

Fuji Manufacturing Co., LTD.

Tokyo HQ: 5-2-24 Matsue Edogawa-ku Tokyo132-0025 Japan TEL: +81-3-3686-2291

U.S.A Sales Rep: Custom Products International Attn: Mr. Rich Nakajima Director of Sales

Burr Removal for Cutting Tools

Prevention of initial chipping, thus expanding the lifespan of the blade edge of a cutter.

Improvement on the durability of the coating by de-burring the surface prior to coating processes.